Straightening Press Application

Straightening presses are indispensable tools in modern manufacturing.

They correct the alignment and shape of metal components that are critical for the mechanical efficiency of critical automotive components, aerodynamic efficiency and structural stability of aircraft, and structural stability of buildings. And, straightening presses can reduce waste by correcting deformations on raw materials and components.

With straightening presses, manufacturing operations have better precision in producing components without decreasing its efficiency and productivity.

What is a Straightening Press?

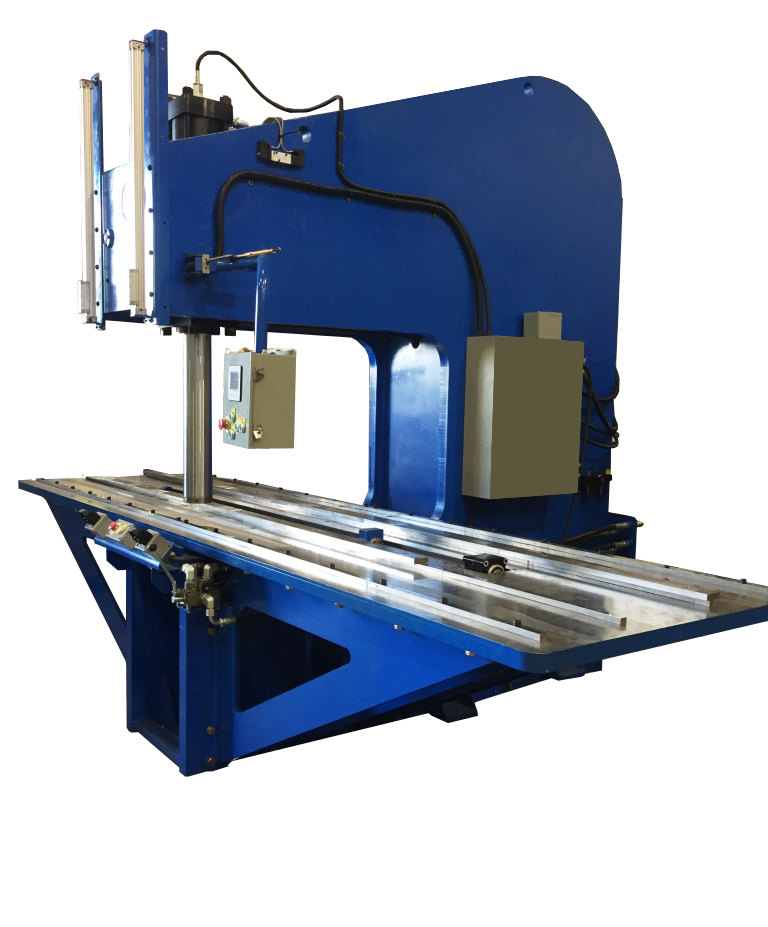

A straightening press is a press used to straighten or align metal and steel materials. They can have wider bolster plates and sometimes lever valve operation for precise RAM control during straightening process. Custom straightening presses sometimes feature a gantry system and pressurized hydraulic system which is operated by positioning the workpiece between rollers or plates of the machine. Once in position, the hydraulic system is triggered to apply the necessary force through the plates or rollers, straightening any blends or warping.

Applications of Straightening Presses

Below are the industries where straightening presses are crucial machines in their operations:

Automotive

Straightening presses are used for straightening axles and shafts due to machining, heat treatment, and forming processes. These are also used for correcting deformation in plates and large weldments due to heat during welding before proceeding with secondary production processes. Lastly, straightening presses are used to test critical automotive components, like crankshafts, axles, and camshafts, for smooth operation and performance.

Aerospace

Straightening presses maintain the integrity of aircraft metal components by aligning them to ensure their compliance to standards and their aerodynamic efficiency and structural stability. Metal parts aligned by straightening presses include wing spars, landing gear components, and fuselage sections.

Construction

Steel beams, girders and other structural elements, and plumbing, heating, and gas pipes in construction are straightened to correct any deformed parts from various manufacturing processes. Straightening presses correct any of the bends, twists, and misalignment that these components get during processing, handling, or transportation to ensure they meet the necessary standards for construction.

Manufacturing

Components made from metal sheets, bars, and tubes can bend, twist, or warp during processing. These deformations can affect the assembly and quality of the final product. Straightening presses are used to correct these issues, ensuring each part conforms to the required specifications.

Advantages of Using Straightening Presses

Straightening presses are critical tools in various industries with the numerous benefits they provide in enhancing manufacturing process and product quality. Below are the specific advantages of incorporating straightening presses in your operations:

High Precision and Accuracy

Straightening presses ensure components meet strict tolerances and specifications for further assembly or its intended use by gradually reshaping it to the desired form with minimal error. This allows manufacturers to have the precision and accuracy they require in high-volume production of high-quality parts, machinery, or products.

Improved Structural Integrity of Materials

Any bends, twists, or warps on structural components compromise their strength and functionality. Straightening presses can correct these imperfections by restoring their original shape, ensuring they can withstand the stresses and loads they are designed for.

Reduction in Material Waste

Straightening presses are beneficial tools in ensuring minimal waste is produced in a manufacturing operation. They can correct any imperfections on components that would otherwise be discarded due to their deformation, which helps in maintaining sustainable manufacturing practices and reducing the cost for purchasing and processing new raw materials.

Enhanced Production Efficiency

Straightening presses can correct imperfections on metal components quickly and efficiently. With it, manufacturing operations have no need for manual corrections or rework, leading to faster production cycles and faster throughput while reducing material waste and cost for purchasing and producing raw materials.

Why Choose Magnum Press for Straightening Presses

Choosing the right straightening press is crucial in ensuring the production of high-quality components and the efficiency of your operations. Magnum Press stands out as your premier choice for straightening presses, with our decades of experience, superior quality, easy-to-repair and maintain designs, customization options, and outstanding customer support.

Expertise and Industry Leadership

For more than two decades, we have designed and built systems tailored for the requirements of countless businesses across several industries. We use the experience we have built up throughout these years to improve the solutions we offer to our customers and innovate developments in our systems.

Superior Quality and Durability

Magnum Press prioritizes quality and durability in designing and building hydraulic presses. We only use the highest-quality materials, and design our presses to be easily repaired and maintained for long-lasting performance, reliability, and durability.

Customization Options

Every client’s requirements for their operations are unique. This is why we offer extensive customization options for our hydraulic press models. And, if any of our current models fall short of their requirements, we can even design and build them a new press from scratch.

Outstanding Customer Support and Service

Here at Magnum Press, we provide our customers with dedicated customer service, from the initial consultation through installation and ongoing maintenance and repairs. And, with our training support and resources, we can help you ensure your team operates your straightening presses efficiently and safely.

Contact Us for More Information

Are you looking for hydraulic straightening presses for your manufacturing operations? Magnum Press can provide a customized solution for your production requirements.

Contact us today for an initial consultation with our team and learn more about the hydraulic press solutions we can offer.