Uses of Hydraulic Presses in Aerospace Innovation

Hydraulic presses are indispensable in the aerospace industry, serving as equipment for forming materials, assembling intricate components, and conducting rigorous testing for quality assurance.

Their unmatched precision and power enable manufacturers to create parts that meet the stringent demands of aviation and space exploration. It’s no surprise that these machines are also at the forefront of aerospace innovation, driving advancements in researching and developing new technologies and designs. As the industry strives for lighter, stronger, and more fuel-efficient solutions, hydraulic presses play a crucial role in shaping the future of both the flight and space industries.

In this article, we’ll explore how these powerful machines contribute to developing next-generation aircraft and spacecraft, including their impact on material science, component manufacturing, and quality assurance, highlighting how they fuel breakthroughs that redefine possibilities in the aerospace industry.

Building Advanced Aerospace Materials

Advanced Composite Materials

Composites like carbon fiber are transforming aerospace by reducing aircraft weight while maintaining strength. These materials are widely used in components like fuselage, wings, and control surfaces due to their strength, lightweight, and corrosion resistance. For spacecraft, they are valuable for body frames and thermal protection. Hydraulic presses play a crucial role in forming these composites, applying consistent pressure to ensure fibers are tightly packed and aligned. This precision yields components that are lightweight and strong, ideal for high-efficiency aerospace parts. Recent breakthroughs, such as thermoplastic composites, offer faster manufacturing and recyclability.

Metallic Alloys

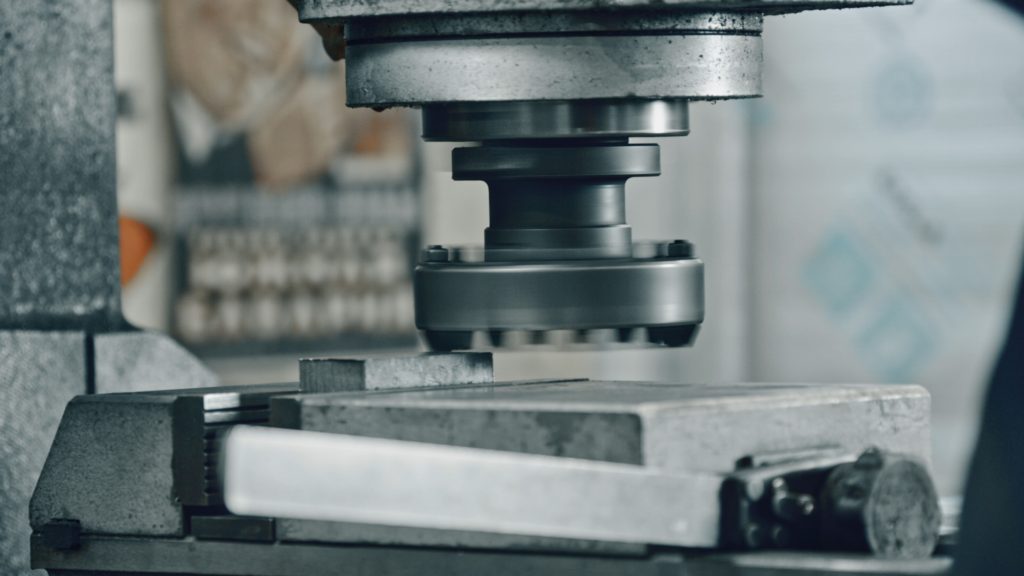

Hydraulic presses are essential for shaping high-performance alloys like titanium and nickel-based superalloys. These materials withstand high temperatures and pressures, ideal for engines and structural components in aircraft and spacecraft. Presses provide controlled force during forming, creating strong, lightweight parts needed in advanced aerospace applications.

Forming Aerospace Components

Aerospace Testing and Quality Assurance

Hydraulic presses are critical in aerospace testing to simulate real-world conditions for components.

Key tests include:

Static load testing

Evaluates structural integrity for wings, fuselages, and landing gear.

Fatigue testing

Tests components under repeated stress to predict durability.

Impact testing

Simulates conditions like bird strikes.

Environmental testing

Assesses components in extreme temperatures, humidity, and vibrations. These tests ensure components meet industry standards for durability, strength, and reliability.

Performing Innovative Aerospace Manufacturing Techniques

Hot Forging

Hydroforming

Supporting Aerospace Research and Development

Hydraulic presses are invaluable for testing and refining lightweight materials designed to withstand extreme conditions.

They support prototyping and developing new manufacturing techniques, enabling faster production cycles and more sustainable practices.

Their versatility allows for precise testing under extreme conditions, making hydraulic presses essential to aerospace innovation.

The Essential Role of Hydraulic Presses in Aerospace

Choose Magnum Press as Your Partner for Innovation

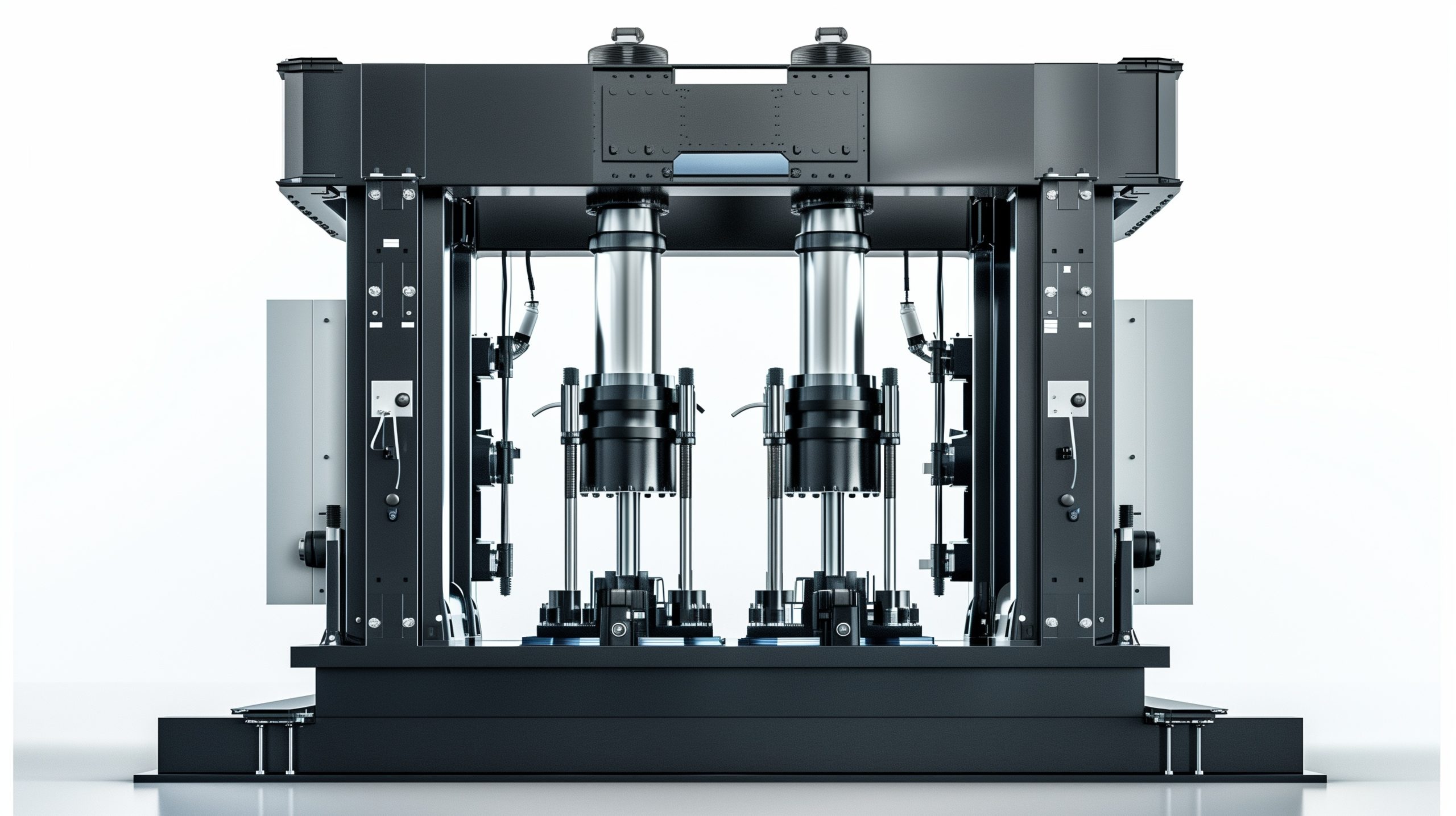

Magnum Press offers industry-leading hydraulic presses designed to meet aerospace demands. Our presses deliver precision, durability, and user-friendly operation. If our standard presses don’t meet your needs, we can design a custom press tailored to your requirements.

With Magnum Press, you get:

Heavy-duty design for tough jobs

Precise and smooth operation

Quiet, efficient hydraulics

Reliable safety systems

Request a quote from Magnum Press for the hydraulic press that meets your aerospace manufacturing needs. Contact us today!