Horizontal Press Series

Horizontal presses are indispensable machines for their orientation, making it possible to handle and manipulate bulky or large-sized material efficiently and safely. They offer superior control and precision, both of which are essential in producing standardized components with little to no deviation. With their versatility, they can be used for a multitude of applications, including bending, straightening, aligning, punching, and shearing.

What is a Horizontal Press?

A horizontal press is a type of machine press used for bending and shaping sheet metal. Its horizontal orientation means it applies force sideways. This makes it beneficial for certain manufacturing processes where lateral access to the workpiece is required or where a workpiece is too large or awkwardly-shaped for vertical-oriented presses. Its orientation allows for enhanced visibility and accessibility for the operator, which can improve precision, ease of operation, and safety during use.

Applications of Horizontal Presses

Tube and Pipe Bending

Tube and pipe bending is essential in creating components for automotive exhaust systems, furniture, plumbing, and various structural frameworks. Horizontal hydraulic presses are instrumental in this application because of their capability to apply precise pressure without compromising the material’s integrity. This allows for creating uniform bends without the risk of kinks and deformities in the finished product.

Straightening and Aligning Components

Due to their ability to apply consistent, directional force, horizontal presses are ideal for straightening and aligning components to ensure they fit and function correctly. They can also straighten structural elements, like metal rods and beams, that have become warped or bent during earlier stages of production or transport.

Punching and Shearing Applications

Horizontal presses are used in mental fabrication, particularly for punching and shearing applications. They have the force required to punch or shear cleanly and accurately for high-quality cuts and holes with minimal material waste. Because of this, horizontal presses are widely used in the production lines of the automotive, aerospace, and electronics industries.

Maintenance and Fabrication in the Rail Industry

The rail industry relies heavily on horizontal presses for the maintenance and fabrication of rail tracks. They are used for bending and straightening rails and other components worn by use and exposure to the elements to ensure optimal performance. And they are used in fabricating various parts for trains and rail infrastructure, like brackets, couplers, and frames.

Advantages of Using Horizontal Presses

Superior Control and Precision for Horizontal Operations

Horizontal presses have superior control and precision, allowing operators to apply force accurately and consistently in various applications. This level of control is critical in manufacturing operations that require high standards of accuracy and products with tight deviations from their specifications.

Efficient Handling of Long and Bulky Materials

With their horizontal orientation and enhanced accessibility and visibility of the workspace, horizontal hydraulic presses are the ideal equipment for applications that involve large workpieces. They also have ample space and support to ensure the smooth operation of positioning and manipulating these materials, reducing the risk of damage to the equipment and workpiece.

Enhanced Safety and Ease of Use

Safety is paramount in any industrial setting. The orientation of horizontal presses provides better visibility and accessibility, which enhances safety during their operations. The better visibility also allows for operators to monitor and control the process more effectively, which enables them to work more efficiently and comfortably.

Versatility in Performing a Wide Range of Tasks

Horizontal presses can perform a wide range of tasks. They can be used for bending, straightening, punching, shearing, and assembling. This versatility allows businesses to utilize a single horizontal press for multiple applications, reducing the need for multiple specialized machines and saving both space and investment costs.

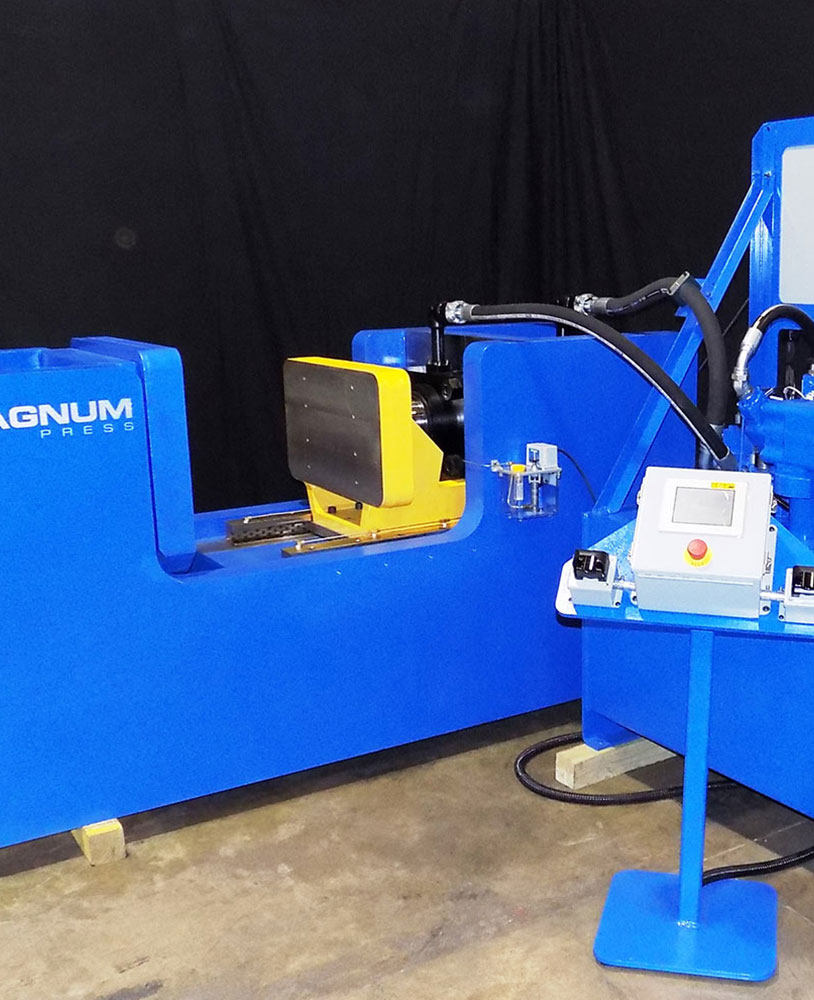

Why Choose Magnum Press for Horizontal Presses

Magnum Press is your best choice for the horizontal press that your business requires. With our industry leadership built on expertise, durability, customization, and exceptional customer service, you can never go wrong with choosing us for your hydraulic presses.

Expertise and Industry Leadership

Magnum Press has been in the industry for decades. Founded by veterans of the hydraulic press industry in 1996, you can never find another high-quality manufacturer that can boast the same magnitude of experience that we have.

Durable Construction and Reliable Performance

We design all our hydraulic presses with durability, reliability, and heavy industrial applications in mind. This is thanks to its robust construction, which allows it to deliver the expected performance and maintain operational efficiency and productivity.

Customization Options

Magnum Press understands that every industrial operation has unique requirements. This is why we offer customization for our hydraulic presses, including converting our vertical presses into a horizontal orientation. We can even design and build a press from scratch that will satisfy your exact specifications, including tonnage capacity and size.

Exceptional Customer Service and Technical Support

Magnum Press is your trusted partner. We are dedicated to your success and ensure this through our services. We offer installation, periodic maintenance, troubleshooting, repair, and training services to ensure your machine is operating safely and efficiently from the start.

Enhance Your Production with Our Horizontal Presses

Ready to improve your production capabilities and capacity with Magnum Press’ horizontal presses? Contact us today to get started! Our team is ready to answer questions and help you find the perfect solution for your industrial applications. Click on the button below to get started!