Coining Application

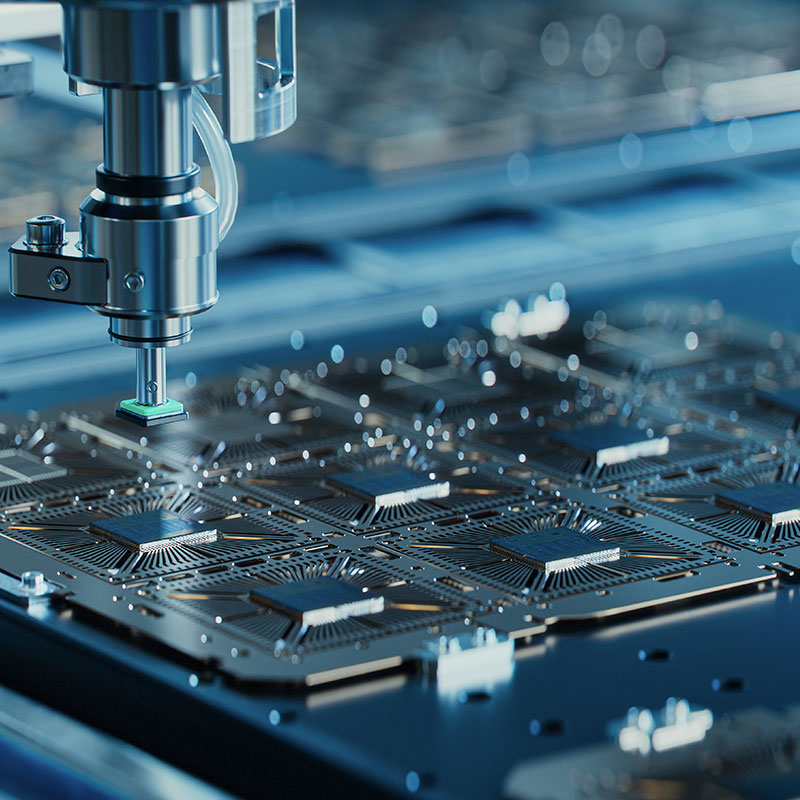

Why Choose Magnum Press for

Coining Applications?

Precision and Consistency

At Magnum Press, precision isn't just a goal—it's our promise. Our coining presses deliver unparalleled accuracy and consistency, ensuring that every coin and embossed product meets the highest quality standards. Whether it's intricate designs or intricate details, Magnum Press presses always deliver flawless results.

Strength and Durability

Built to withstand the demands of intensive coining operations, Magnum Press presses are engineered with strength and durability in mind. From robust construction to heavy-duty components, our presses are built to last, providing longevity and reliable performance that you can count on, day in and day out.

Operational Efficiency

In today's fast-paced production environments, efficiency is paramount. That's why Magnum Press coining presses are designed for maximum efficiency, featuring rapid cycle times and minimal maintenance requirements. With streamlined workflows and user-friendly controls, our presses optimize productivity, allowing you to focus on what matters most – creating exceptional coinage.

Applications in Coining

Our Hydraulic Press Range for Coining

M2P Series: The Compact Champion (10-12 Ton)

Ideal for small minting operations or intricate coin designs, the M2P Series provides exceptional value without compromising performance. Featuring a user-friendly design and compact footprint (perfect for smaller workshops), these coining presses offer capacities ranging from 10 to 12 tons. The M2P Series ensures precise control and repeatability for high-quality, small-scale coin production.

M4PF Series: The Mid-Range Maestro (60-200 Ton)

For mid-sized minting operations requiring increased production volume or handling larger coins, the M4PF Series is the perfect solution. This versatile series boasts capacities from 60 to 200 tons, along with robust construction and reliable hydraulic systems. The M4PF Series prioritizes user safety with integrated features and delivers consistent, high-quality coin production for medium-scale operations.

Dominator Series: The Industrial Powerhouse (Over 300 Ton)

For large-scale, high-volume coin production, look no further than the Dominator Series. These industrial coining presses exceed 300 tons of force, making them ideal for minting large coins, tokens, or medals. The Dominator Series is engineered for unmatched power, durability, and precision, ensuring flawless results for even the most demanding coining projects.

Key Features and Advantages

Across the Range:

Customization Options

Tailored to Your Needs